La electricidad impulsa casi todo lo que usamos a diario, desde electrodomésticos hasta maquinaria industrial. Pero, ¿sabías que existen diferentes tipos de electricidad con características

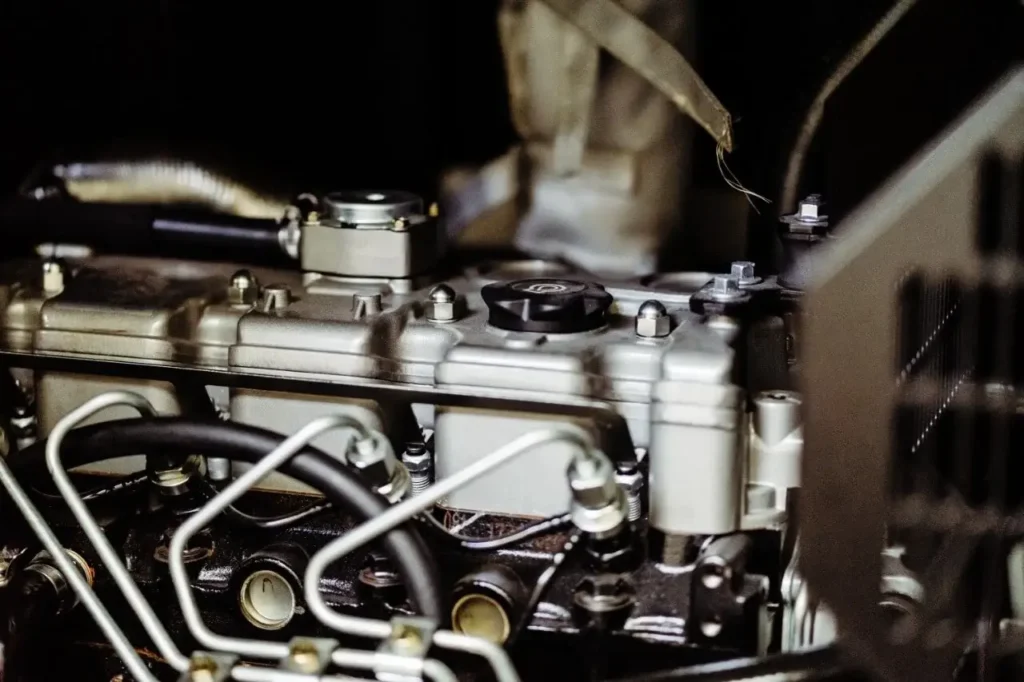

For decades, Perkins engines have supported the tasks where power and efficiency are required. Ninety years in the market prove its quality. They have evolved and improved over time. Their designs and construction have been perfected to be applicable in the most diverse fields. They can be used in industry and construction, in agriculture, obviously in transportation, and especially in power generation.

This versatility is the result of meticulous design and careful attention to technical details by virtue of the motors' intended use. In this way, the technical specifications of each model obey the requirements that its specific work will demand.. That is why there are so many models: to cover the particular needs of a task, to provide a satisfactory technological solution of power and efficiency.

Next, we will take a look at the history of Perkins engines. We will see why today, after almost a century, they continue to be a benchmark in power solutions for work. We will also see in what lies its quality, its efficiency and its versatility. Namely, what are those characteristics that make Perkins engines one of the best options available on the market, given the advantages it offers.

In 1932, in Peterborough, England, two engineers -Frank Perkins and Charles Wallace Chapman- designed and built a high-speed diesel engine, completely new and disruptive compared to the conventional engines of the time, which ran on gasoline. It was a great challenge, as the first prototypes were excessively large and robust, which made their functionality and adaptability to the vehicles of the time questionable.

Nevertheless, the fact that it was considered competitive with gasoline engines was significant. Over the years, its design was perfected, and diesel models - especially the Vixen - became increasingly popular. They were four-cylinder engines, with great power and, what made them relevant in the market: they were fast.

Later that same decade and during the following decade, the P4 and P6 series, engines designed by Chapman, began to become popular. They were more compact engines than the Vixens. That was its main characteristic. But not because they were smaller were they less powerful. On the contrary: the P6 had about 85 horsepower, producing 63KW, and an incredible angular speed of 2600 rpm.

The quality of these early models was and is widely recognized. During the 20th century, they gained a reputation for being large, robust engines, but also powerful and efficient, as well as economical. Thus, the main automotive brands took notice of these engines and began to implement them in their production lines. Both heavy-duty automobiles and private transport vehicles began to have Perkins engines.

Beginning in the year 2000, the design and production of Perkins engines became even more diversified. The technical needs that had to be met were raised, and as a consequence, the technical specifications that the new models should have were thought out. In this way, in the industrial, energy, marine, transport and agricultural fields, there were more options to choose from.

Currently, it is estimated that there are around 22 million Perkins engines in the world, fulfilling the most varied tasks where strength, speed and efficiency are required. There are light, compact (just two cylinders) and versatile Perkins engines, such as the 400 series. There are other larger and more robust, more powerful, with six cylinders, eighteen liters and a capacity to generate up to 800hp, or about 600KW, designed for hard industrial work, such as the 2800 Range.

As has been said, Perkins engines are versatile. The tasks for which they are used are the most varied and dissimilar, although they all have in common the need for power and efficient force. Some applications have been mentioned.

In transportation, brands such as Mercedes-Benz, Rover, Plymouth or Chevrolet, among many others, have used these engines; Of course, with peculiar characteristics: since their purpose is to provide mobility to an automobile, they must be light and have considerable resistance for long and sustained efforts.

The same happens with industry, in construction and agriculture, where Perkins engines are also used. They are well-defined tasks, which demand an equally defined effort. The same thing happens in the field of electricity generation: motors with certain characteristics are required, which depend on the use.

Although the objective is the same, namely to generate electricity, It is not possible to use the same engine model for all models of electric generators. Why? For physics, simply: electric generators work thanks to Faraday's law, according to which, in the phenomenon of electromagnetic induction, there is a proportional relationship between the speed of a magnetic field on a conductive material, and the induced voltage that is stimulated in the material.

In other words: taking into account that the motors run at different angular speeds (ie have different rpm), the induced voltage or generated current will also be different. Therefore, for an electric generator that is going to require little, a low-power, low-rpm motor is suitable. On the contrary, a generator that requires a considerable amount of current must have a robust and powerful motor, capable of supplying such demand.

Our generators, for example, have Perkins engines from the line 400 EP and of the line 1100 EP (electric power). They are engines, above all, resistant, with a highly durability, and suitable for long and demanding jobs.

Specialized for the generation of electrical energy, from the less powerful generator engine (the 403D-11G generator engine JP10E), to the one with the highest power (the 11044D-44TG1 of the generator JP60E), these engines are designed to operate efficiently for a long period of time. They are motors capable of going at different angular speeds, from 500rpm to 1800.

The characteristics of the motors vary from model to model. For example, two of our available models (the JP10E and the JP 25E), they have two engines whose designs and specifications are very similar: both have four-stroke engines, they have three in-line cylinders, their fuel injection system is mechanical, their starting system is electric.

However, they are capable of different powers (between 8 and 11 KW the first, and 14 and 18 KW the second), because what changes in these engines is their displacement (the first has a cylinder diameter of 77mm and the second with 84mm).

We see that the small technical differences between the engines result in different operation, performance, efficiency and power. In other words: they are specifically designed to work in the generators whose structure they are part of.

We invite you to learn more about the characteristics of Perkins engines and our generators.

La electricidad impulsa casi todo lo que usamos a diario, desde electrodomésticos hasta maquinaria industrial. Pero, ¿sabías que existen diferentes tipos de electricidad con características

La electricidad es una parte esencial de nuestras vidas, desde el encendido de una simple bombilla hasta el funcionamiento de industrias enteras. Pero, ¿alguna vez

Elegir el aceite correcto para un generador de luz es fundamental para asegurar su rendimiento óptimo y prolongar su vida útil. Sin embargo, muchas personas

En un mundo cada vez más dependiente de la energía, contar con una planta eléctrica para casa se ha convertido en una necesidad esencial. Ya

In a world where sustainability is no longer just an option, but an urgent necessity, renewable energies stand out as the key to

In the current context, where sustainability has become a global imperative, it is crucial to understand which energy sources are renewable and how