Tipos de Electricidad: Corriente Alterna, Continua y Otras Formas

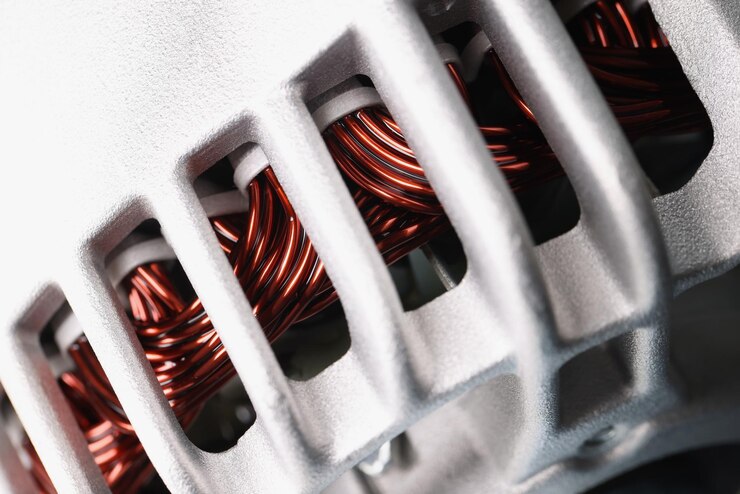

La electricidad impulsa casi todo lo que usamos a diario, desde electrodomésticos hasta maquinaria industrial. Pero, ¿sabías que existen diferentes tipos de electricidad con características